Size USE TORQUE Lubricant

1/4 - 20

Oil pump cover

80 lb. in.

(oil, unless noted)

Oil pan to front cover

80 lb. in.

Front cover

75 lb. in.

Rocker cover

25 lb. in.

antiseize

5/16 - 18

Oil Pan bolt

165 lb. in.

Camshaft Sprocket

20 lb. ft.

3/8 - 16

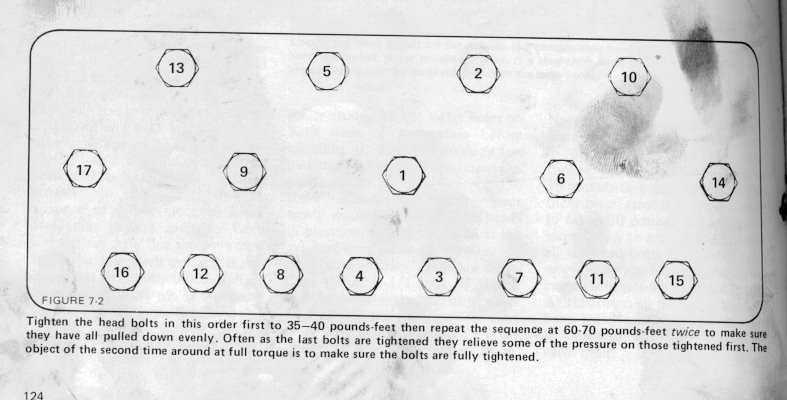

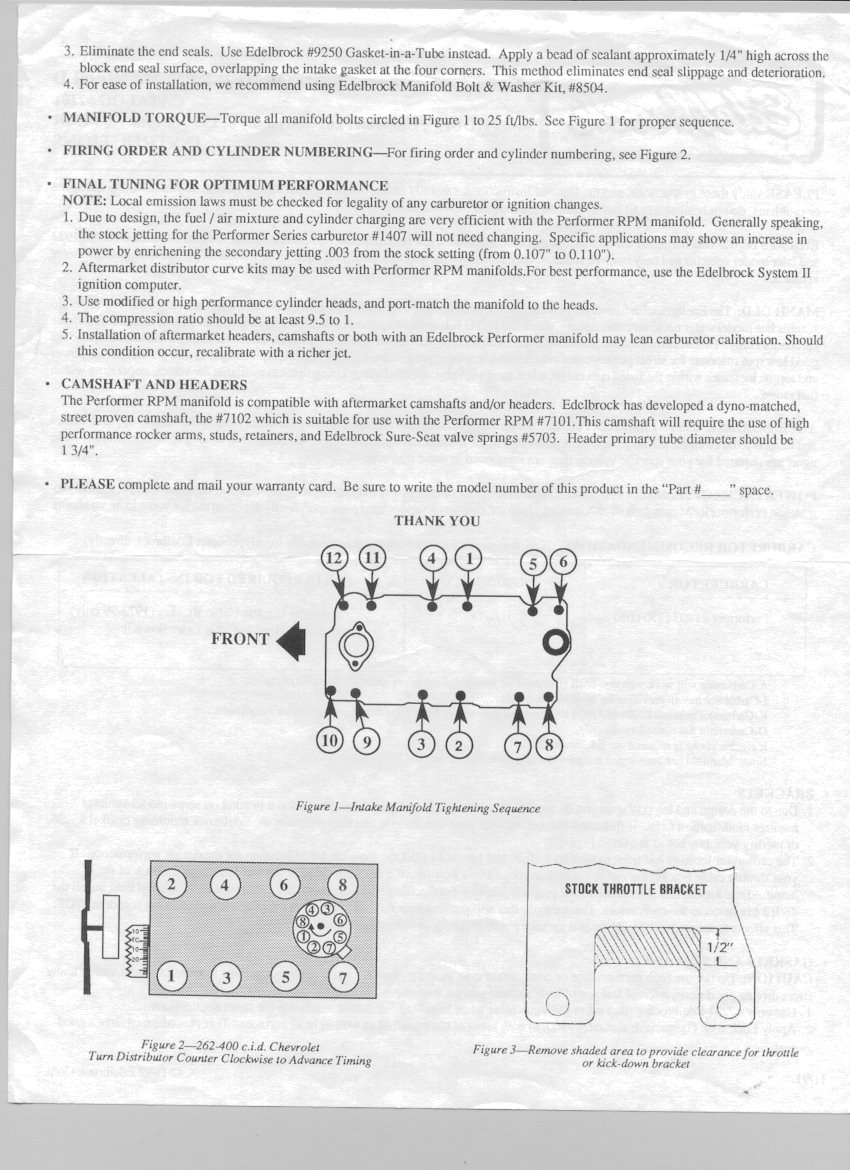

Intake manifold

25 lb. ft.

Water Outlet

20 lb. ft.

Exhaust manifold

25 lb. ft.

antiseize

Clutch pressure plate

35 lb. ft.

Distributor clamp

20 lb. ft.

Flywheel housing

30 lb. ft.

Flywheel

60 lb. ft.

Locktite

Water pump

30 lb. ft.

Sealant

3/8 - 24

Rod bolts

50 lb. ft.

Locktite (0.006" stretch, frequently 55-60 lb.

ft. required to obtaim proper stretch)

11/32

early rod bolts

35 lb. ft

Locktite (0.005" stretch)

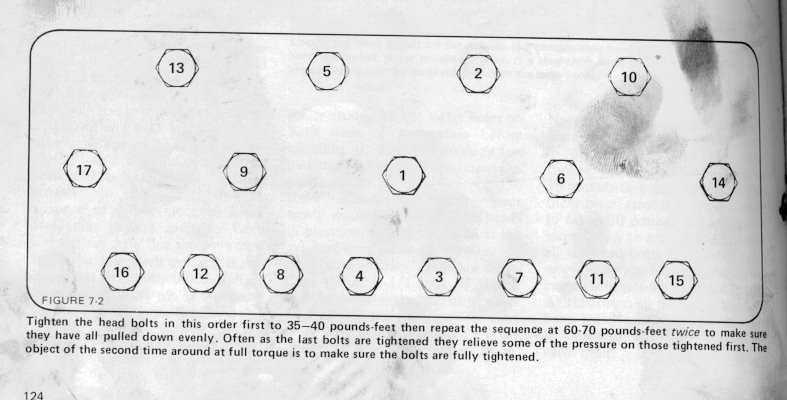

7/16 - 14 Head bolts

65 lb. ft.

Sealant

Rocker arm STUD

50 lb. ft.

Oil pump

65 lb. ft.

1/2 - 13 Main

bearing (inner)

70 lb. ft.

(outter)

65 lb. ft.

1/2 - 20 Harmonic balancer 85 lb. ft.

Oil filter canister

25 lb. ft.

Oil drain plug

20 lb. ft.

1/2 - 14 Temp sender unit 20 lb. ft.

14mm Spark

plugs (13/16 hex)

25 lb. ft.

( 5/8 hex)

15 lb. ft.

Head bolt sorque sequence

The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as recommended by the manufacturer. ARP is adamant about using a special moly lube or ARP thread sealer for use with their stud packages. ALWAYS follow the manufacturers instructions for best results.

Here are a few scans of instructions from Edelbrock that seems to be very usefull.

Aluminum (aftermarket) heads and intake manifolds

require a different torque than stock cast iron units.

Common assembly clearances

(ALWAYS consult your piston manufacturer for recommended clearances. Many pistons require a tighter bore)

Piston to bore

0.0055 - 0.0065" ( measured at centerline of wrist pin, perpendicular to

pin)

Piston ring gap

MINIMUM end clearances Top

0.022"

2nd 0.016"

Oil 0.016"

Wrist pin 0.0006 - 0.0008" in piston, 0.0008 - 0.0010" in rod for full floating pin (End play 0.0 - 0.005"

Rod bearings 0.002 - 0.025" , side clearance 0.010 - 0.020"

Main bearings 0.002 - 0.003" , 0.005 - 0.007 crankshaft end play

Piston to head clearance 0.035 MINIMUM including gasket (steel rods), 0.060" MINIMUM aluminum rods

Valve to piston clearance

MINIMUM 0.020" exhaust , 0.010" intake NO VALVE FLOAT

Recommended: 0.080 intake, 0.100 Exhaust (steel rods) 0.100 intake, 0.120

Exhaust aluminum rods